New Tire Thermal Model – a (r)evolution in Avehil simulation

On the hunt for driving inaccuracies with the best of accuracy: the new real 7me, DIL 7re thermal model has come to life.

Thermal Model

There is always the risk that simula7on tends to be a very precise, repeatable, but inaccurate system, i.e., one that returns sensa7ons to the driver that are far from real driving; the human element, on the other hand, tends to be very accurate, driving the same way as in real life, but he is (usually) not very precise.

In the Driver In The Loop simula7on, one of the most ambi7ous goals is to get these two elements to talk to each other in the correct way, so as to have a result that best combines precision and accuracy: to strive for maximum accuracy with precision.

Understanding 7res behavior is a key factor in this process, and motorsport in general, that can make the difference between winning or losing races. Therefore, we put our effort on developing a physical thermal model that could replicate the thermal status evolu7on of surface and internal layers of a 7re during its opera7ng 7me.

We can say now that our 7re model is ALIVE.

The Avehil’s Tire Thermal Model behave like a real 7re; it responds to the warm-up dynamics as its physical counterpart responds. And we developed specifically for DIL so we can convey it to the driver during simula7on sessions.

Robustness and reliability of our model has been obtained comparing the simula7on with data acquired on track with VESevo® and TRICK®, thanks to our technical partnership with Megaride and the experience gained on track alongside racing teams, on real cars, with real data.

Moreover, we focused our aUen7on on improving computa7onal efficiency in order to allow live simula7on in DIL (Driver in the Loop) environment. This is definitely a step forward to driver awareness in terms of balance evalua7on during run sessions, performance sensi7vity for specific track and 7re management.

Hard challenge is “clocking” the model computa7on 7mes limit below 1/400th of a second, to deliver truly real 7me responses to the driver during the simula7on. This one is well known as the real challenge in Windows ambient: when you must compute so many variables in such a short 7me you need a computa7onal algorithm that is op7mized as best as possible.

Now let’s have a deeper look into the model.

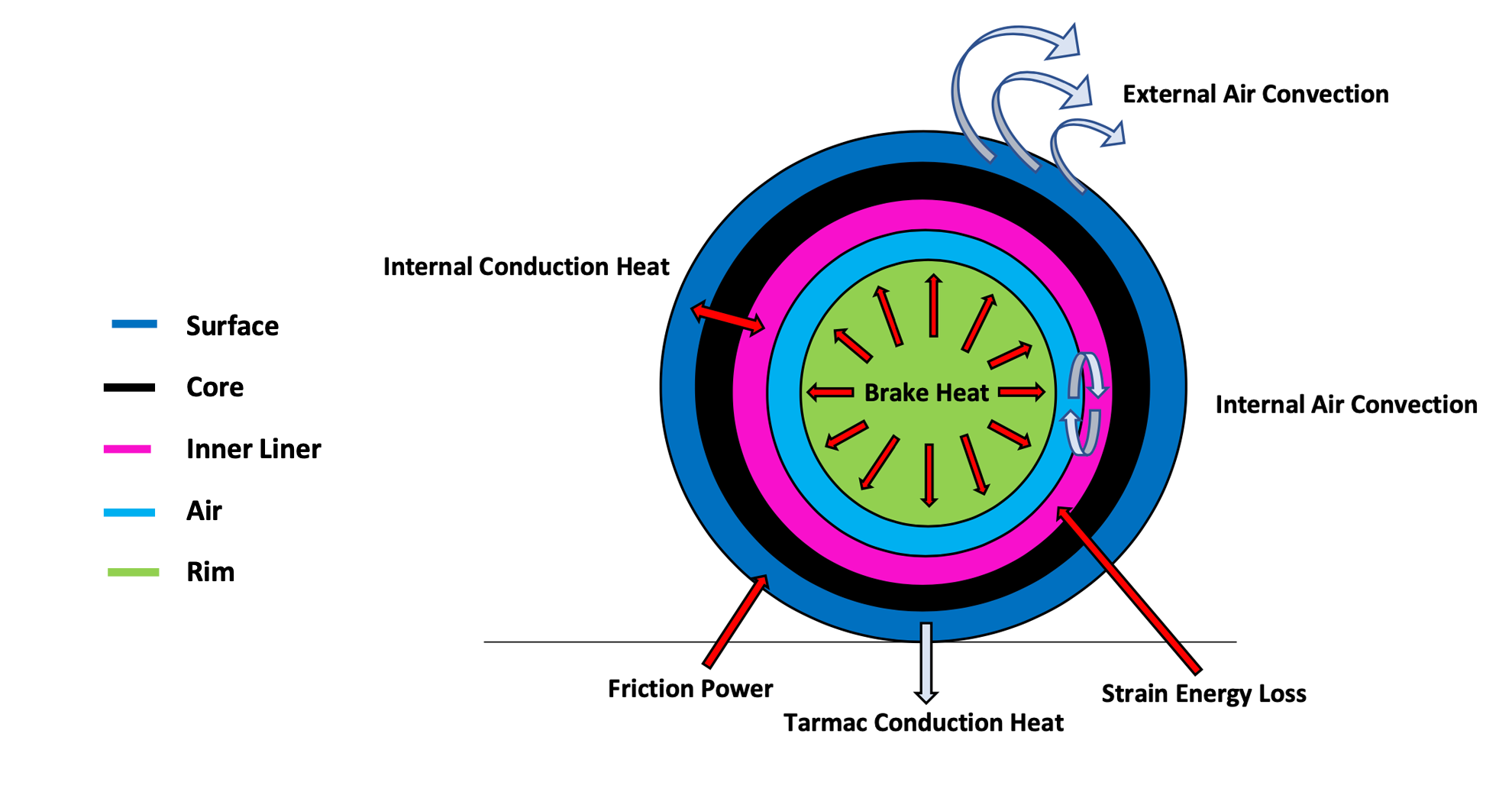

The physical model is based on a system of Fourier heat diffusion equa7ons that take into account the heat produc7on and heat exchange phenomena inside the 7re and between the 7re and the external environment. Such equa7ons are fed by data that come directly from the vehicle, thermal characteris7cs of the tarmac and the external ambient. Thanks to our work of correla7on between real data and simula7on together with the technical contribu7on of Megaride, we gave to the model an absolute value in terms of robustness and reliability in every track and every ambient condi7on.

The 7re is modeled with 4 layers in addi7on to a 5th layer that represents the rim.

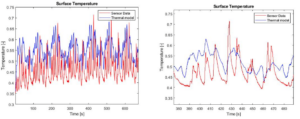

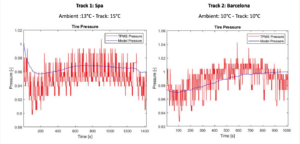

The 1st layer models the 7re surface and replicates the produc7on of fric7on power and conduc7on heat exchange between the tarmac and the 7re and the convec7ve heat exchange between the 7re and the external air. In par7cular, the fric7on power depends on contact patch area and slip condi7on of the 7re with respect to the tarmac. These aspects are all included in our thermal model with the addi7on of camber sensi7vity on 7re contact patch. In the following graphs a comparison between real data from the track and simula7on of our model is presented on three different circuits, ambient and tarmac condi7ons. The results are normalized with a reference temperature for confiden7ality reasons.

Track 1: Spa

Ambient Temperature: 13 °C – Track Temperature: 15 °C

Track 2: Barcelona

Ambient Temperature: 10 °C – Track Temperature: 10 °C

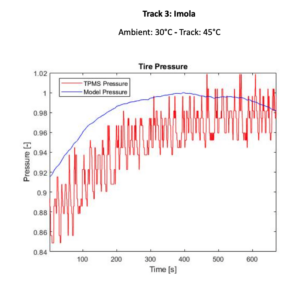

Track 3: Imola

Ambient Temperature: 30 °C – Track Temperature: 45 °C

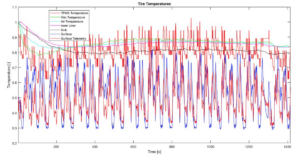

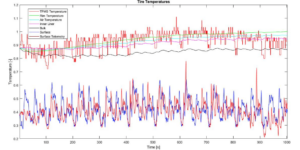

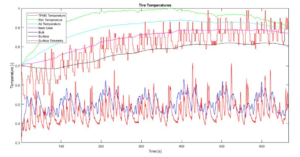

The internal layers replicate the temperatures of the core (2nd layer), inner liner (3rd layer) and internal air (4th layer) of the 7re modeling heat exchange between the different layers, energy produc7on due to hysteresis cycles and natural or forced convec7on of the internal air that interacts with the inner liner and the rim. The laUer is modeled as the final layer and its temperature is influenced by the heat exchange with hot brakes, which phenomenon is also taken into account in this model.

Track 1: Spa

Ambient Temperature: 13 °C – Track Temperature: 15 °C

Track 2: Barcelona

Ambient Temperature: 10 °C – Track Temperature: 10 °C

Track 3: Imola

Ambient Temperature: 30 °C – Track Temperature: 45 °C

Furthermore, beside the calcula7on of infla7on air temperature the model incorporates a module for the calcula7on of internal air pressure. Below, a comparison between real data and our model simula7on is given

Skydrive is constantly looking for innova7on in race cars DIL simula7on. Our main objec7ve is not to develop a race car, but to integrate the drivers and the cars in a unique system to replicate some condi7ons that they would find during race weekends. It is well known that now a day, modeling suspensions, chassis, aeromaps is not too difficult but 7res are undoubtedly the crucial stage. That’s way we work on “the field” with our clients.

That’s way our efforts on understanding the physics behind the 7re, that we believe is a fundamental component integrated with a reliable mathema7cal model of a race car. The new thermal model is only the beginning of our technical (r)evolu)on, which include as second step the implementa7on of a new advanced wear model.

The target is set, and we are already working on it. Stay tuned, other details will be revealed soon!